In view of my wife’s opinion* (outrageous!) that I’m accident prone (what about mitigating circumstances?), I endeavor to take a most overcautious stance regarding work safety. So, to this point the engine has been running with fuel supplied from a gas can connected to the fuel pump hose. There’s no gas in the gas tank yet. That’s because I’m completing body repairs in the rear of the car. Welding and grinding creates heat and sparks — very dangerous near gas fumes.

Most of the body of the ‘66 Thunderbird is double-walled, with exterior and interior walls welded together at the edges, forming a strong structure resistant to bending and vibration. The downside is that (1) it makes the car very heavy and (2) water and moist dirt have a tendency to become trapped in between the walls at the bottom joints causing rusting from the inside to the exterior surfaces of both walls.

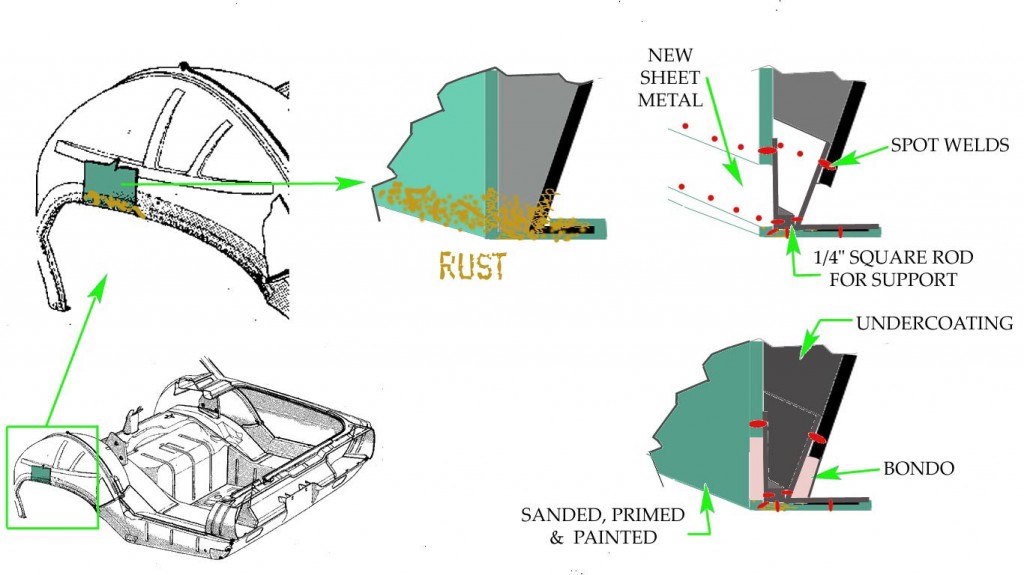

The accompanying diagram shows the left wheel well area.

In this case the rust had eaten through both walls and also weakened the structural integrity of the wheel well curvature. It’s best to make repairs to an acceptable standard of industry practice. In cases where rust has completely eaten away the metal, I start by cutting away the rusted areas leaving solid metal, then welding in new sheet metal using a MIG welder.

In this particular area, cutting away the rust left nothing to weld new metal to. Also needed was a solid restoration of the wheel well curvature. For that I used a length of ¼” square rod, bent to the wheel well curvature and welded to where the existing metal was still solid.

Before welding in new metal, the existing metal is thoroughly cleaned of rust and treated with Eastwood™ Rust Converter to ensure that the area won’t oxidize further. (Note that the Rust Converter is great stuff but, at about $32/quart + shipping, is expensive.) Once the new metal is welded in place the weld spots are smoothed with a grinder. Next, Bondo is applied and sanded smooth (repeating until the surface conforms perfectly to body contours). Rubberized undercoat is applied to the interior joints and wall surfaces to seal them from moisture so that they never rust again. The undercoat also serves to quiet the car. Then the exterior surfaces are primed and painted.

| The car doors had been removed in order to have access to the car’s interior and to make it easier to restore operation of the windows and locks. The rust on the doors was not as severe as the rear quarter panel discussed above. | ||

|

In this case the rust had created pin-holes in the metal but didn’t eat away enough of the metal to require new metal inserts. To repair pin-holes, both sides of the panel are sanded then treated with Rust Converter. A fiberglass patch is applied to the interior of the panel, followed by a thin coat of Bondo on the exterior. The interior is undercoated. |

If you’re doing this for your own car there are two products I recommend that will save money. To seal joints, apply with a brush Henry™ Plastic Roof Cement (available from Home Depot for about $9/gallon). The other product is the Rubberized Undercoating available from Harbor Freight, less than $5 for a large spray can.

Cheers!

PS…

*Do note that I adore my wife. Although I portray her in the She-Who-Must-Be-Obeyed stereotype, that is merely a literary device. She is without doubt the best that’s ever happened to me. For too many years I avoided getting married, living a life of international travel and the freedom to adventure as I pleased. That’s a great life for a young man, but along the way I met men like me who had grown old, bitter, and lonely because they never married. The woman who is now my wife rescued me from that fate.